3Series Aluminium Alloy Extrusion

Product Details

product description:

Features:

3 series aluminum alloys with manganese as the main alloy element cannot be heat-treated and strengthened, with good corrosion resistance and good welding performance. Good plasticity. (Close to super aluminum alloy). It can also be called anti-rust aluminum alloy.

Scope of application:

seamless oil-conducting pipes used in aircraft, cans, air conditioners, refrigerators, and car bottoms in humid environments.

The following are the 3 series aluminum alloys that we can produce:

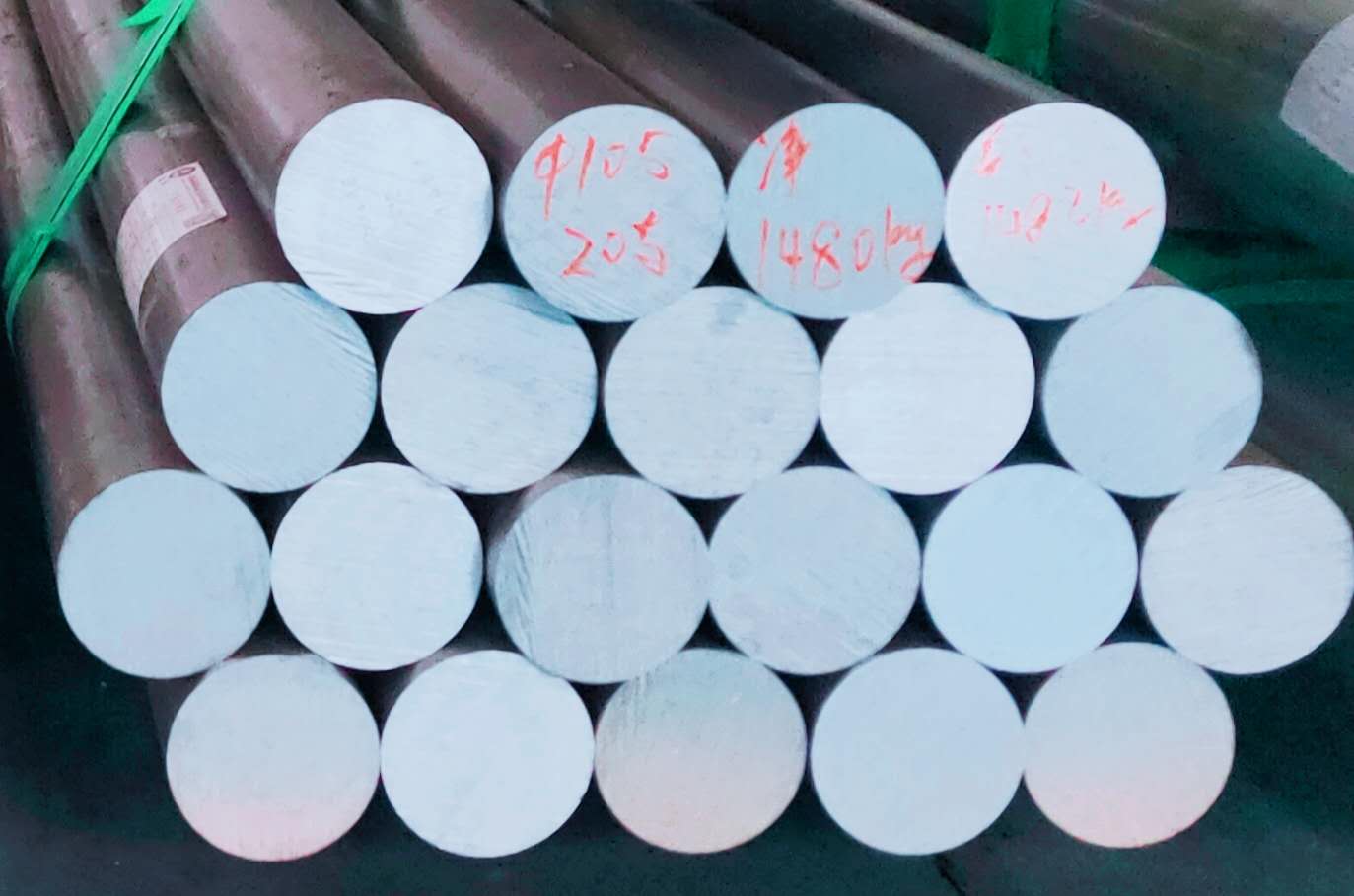

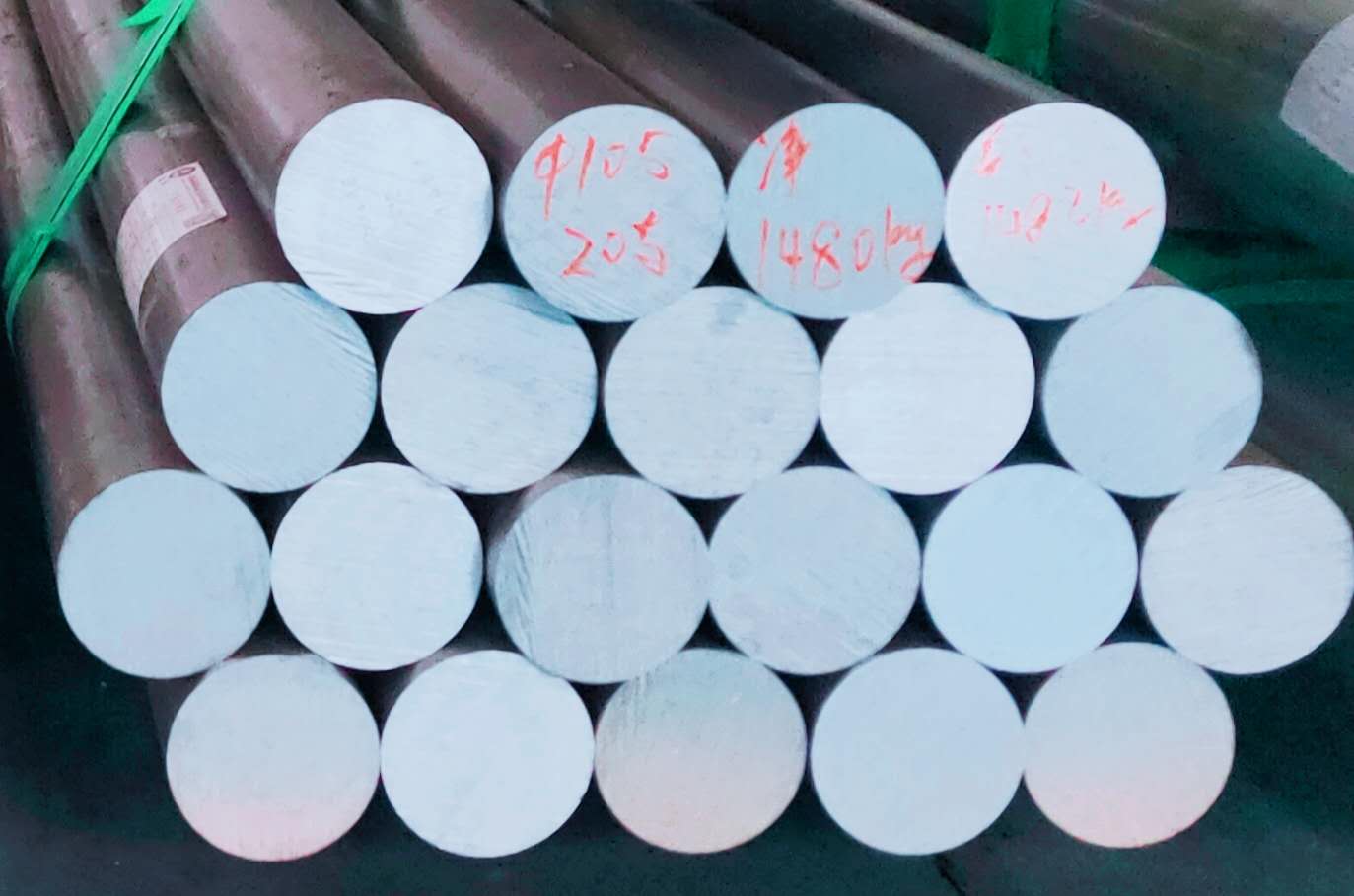

Temper: H112 Alloy: 3a21 Length: 7m-14m product diameter:100mm-600mm

Product:

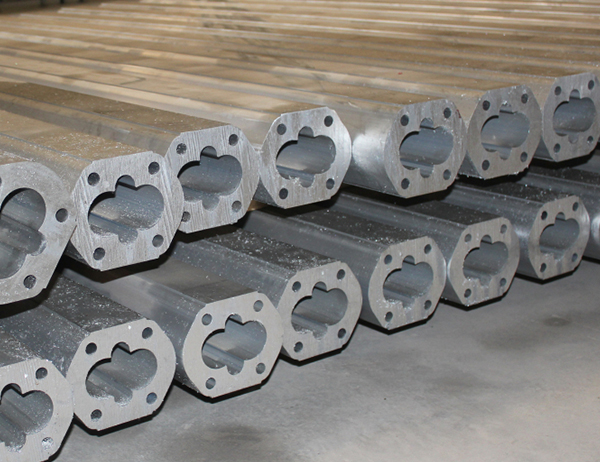

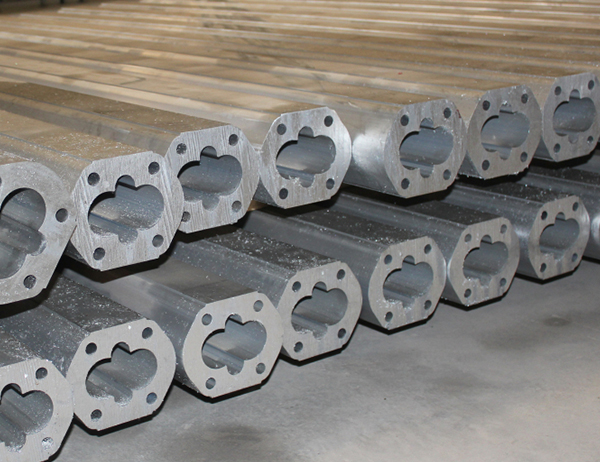

(1)luminium Alloy Tube,

(2)Aluminium Alloy Bar

(3)Aluminium Alloy Extrusion Profile

Package:

(1)Bare Package;

(2)Waterproof Cloth / Plastic Film Wrapping, Steel Band Bundling, Wooden Pallet Bottom;

(3)Cube Packaging, Wooden Pallet Bottom, Steel Band Bundling

Product advantages:

(1) Sophisticated production technology, advanced equipment. The main production equipment and testing equipment are imported from abroad

(2) High precision, high strength, corrosion resistance and wear resistance

(3)The technical center (central laboratory) has been assessed as the Qinghai Engineering Technology Center. It is not only capable of analyzing the chemical composition of the aluminum alloy tube and rod production, metallurgical structure inspection, and mechanical property testing, but also can meet the needs of new product and new process development.

(4) Certificates to prove quality:

Knowledge

Whether you are looking for the first profile drill bits to help you begin drilling or if you are in the market for a new set of tools, it is important that you understand the difference between aluminum profile manufacturers and drill bits. While the core benefits that aluminum profile makers offer is similar to other drill bits such as diamond and ceramic, they are still a bit different when it comes to how they are made. If you have never purchased a drill bit before, it may seem confusing at first, but with a little bit of information, you will understand exactly what it means when you are shopping and what to look for. With this knowledge, you can begin to find the right types of aluminum profile drill bits to meet your needs.

The most important thing to remember when shopping for aluminum profile drill bits is the material they are made from. Drilling holes into any type of metal, including sheet metal with an aluminum core, can create a sharp edge that can cut your drill bit or damage the material the bit is made from. For this reason, it is important that you only purchase drill bits that are made from materials that will not hurt your hands or harm the edges of your drill bit. Some common drill bits are not made from the same material as their counterparts, so if you do not already own a set of drill bits made from the material you need, it is important to ask your supplier about which drill bits they recommend.

One of the most common materials used to make aluminum profile drill bits is aluminum oxide. This is a naturally occurring product that is found throughout the Earth's crust. Because of this, it is very unlikely that you will run into a supplier that does not offer this as an option for their customers. If you do not have an aluminum oxide drill bit, it is likely that you will not be able to find one that is compatible with your drill bits, which could limit your ability to drill into certain types of metals. If this is the case, you can try looking for a supplier that offers a large selection of alloy drill bits that can also produce aluminum oxide.

Another popular alloy that is used by aluminum profile makers is steel. There are a wide range of steel alloy options that can be used to make the bits you need. These include such widely used products as iron and steel, which are commonly used in applications related to plumbing and other heating and power generating equipment. It is a good idea to ask your supplier what type of drill bit they recommend for your specific application.

One reason why some manufacturers prefer to work with steel rather than aluminum profile drill bits is because steel has a higher heat conducting characteristic. The higher the density of steel, the more conductive its heat will be. Because of this, drill bits made of this material will be able to trap more heat from the drilling process, resulting in faster and more accurate drilling. Because of this, many drill technicians prefer to use these types of drill bits when working with metals that are difficult to drill into using standard drill bits.

Another benefit of using steel as the main ingredient in their aluminum bits is that it is generally easier to shape than aluminum. This is due to the greater amount of "structure" that steel offers. Structure refers to the ability of a drill bit to be bent into different shapes with the force of a varying pressure. For example, the bit could be bent into an arch if placed under tension at a particular angle. While the structure might not directly benefit your business, it is often times easier for many of your employees to understand how to use this type of drill bit in comparison to an aluminum or steel drill bit. Because of this, many employers tend to prefer to use steel as their main drill bit choice over other metallic drill bits.

Shipment:

Standard loading quantity:

1*20GP:Max .length:5.85 meters Loaded quantity: 10 to 12 tons

1*40HQ:Max. length:12 meters Loaded quantity: 22-26 tons

Standard export port:

Huangpu/ Foshan or Shenzhen

Type of shipping:

Shipment by sea; by road; by train; multi-transportation.

Factory