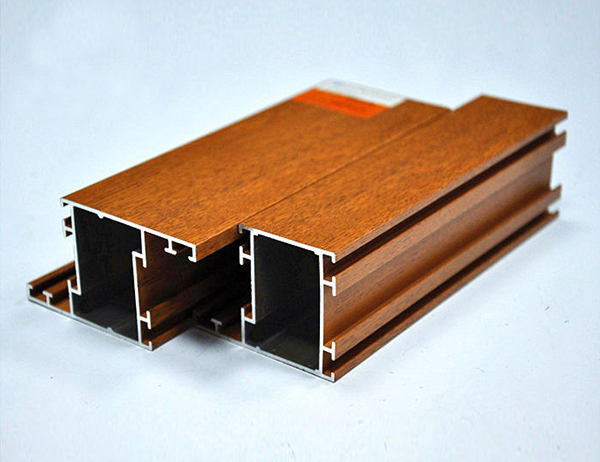

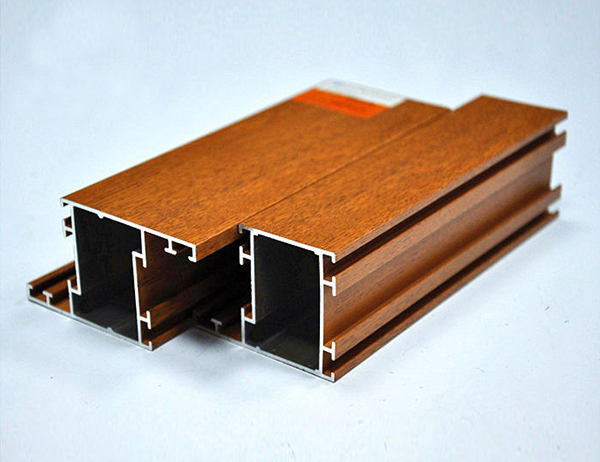

wood aluminum profiles for indoor

Product Details

Our company holds global updated production equipment and quality inspection system, the surface processing include series of aluminium profiles that have been subject to the processes of mill finish, oxygenation, electrophoresis, polishing, powder spraying, PVDF, wet painting, wood grain transfer, thermal break and insulation, and used for such four majors fields as door and window, curtain wall, decoration and industry.

The picture is wood grain transfers and mainly use for indoor.

Features:

1. a wide range of colors, specifications complete, according to international color code production of more than 200 kinds of aluminum profiles of different colors, beautiful and generous, very high grade European architecture sentiment.

2. good corrosion resistance, salt spray performance is particularly good.

3. good weather resistance, coating can be maintained for more than 30 years without powdering, light loss rate and discoloration rate reached at least one level.

4. good wear resistance, hardness is greater than 2h.

5 resistance to mortar corrosion, easy construction.

6. the coating has good combining ability. When the profile is bent, the coating is not cracked, and it is suitable for all kinds of shape modeling and processing.

7. not easy to adhere to greasy things, easy to clean, scrub.

When purchasing an aluminium section maker, it is imperative that you take your time in doing research to ensure that you are buying the one that is right for your needs. This is because different manufacturers provide different products with different levels of quality and functionality. Therefore you need to know what you are looking for to find the most suitable aluminium section maker for your needs and budget. There are a few key things that you should consider when looking to buy an aluminium section maker.

The first thing you will want to look for when buying an aluminium section maker is the material it is made from. You will find that some are made from high carbon steel while others are made from high quality aluminium. The former is considered to be more durable than the latter however it is a lot heavier and may not be as portable as some other section makers. It is important therefore that you factor this into your decision when purchasing such a product. Also, check to see what is the manufacturing standard used in making the sections.

Another important consideration is the speed at which the aluminium section maker can produce sections. You should check if the product you are interested in can produce sections within the shortest time possible. Some aluminium section makers can produce sections in as little as 10 minutes. Others though can take up to three days to manufacture a single section. It is therefore important that you consider how much you want to be able to get done in the shortest amount of time.

Check the capabilities of the aluminium section maker as well. Some of them are only able to section small materials whilst others are capable of sectioning large pieces. It is therefore important that you choose a section maker that has the capabilities that match what you are after. If you are looking for something that can produce numerous sections then opt for an aluminium section maker that has more capabilities.

Consider the maintenance of the aluminium section maker that you are interested in. Some of the section makers are very easy to maintain. They are usually self contained and do not require any special attention. Others though can require some careful handling. Before choosing one though, it is important that you find out all you can about how easy they are to clean.

There are many more considerations that go into choosing an aluminium section manufacturer. The ones that are listed above are just a few of the most important considerations that you will need to make. Remember to also look into the warranty that comes with the product as this is a very important factor. In addition, you may want to check online feedback to help make your choice.

Factory