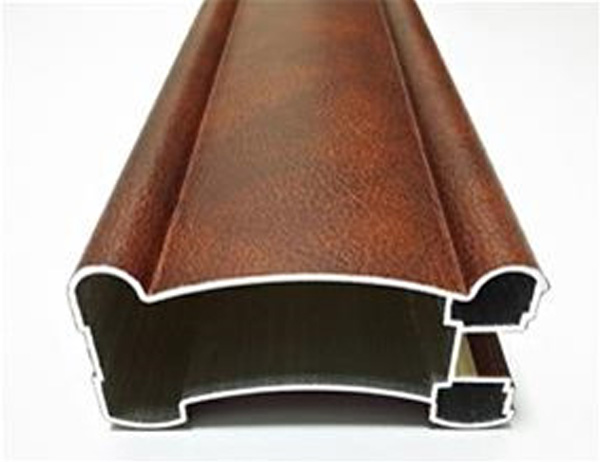

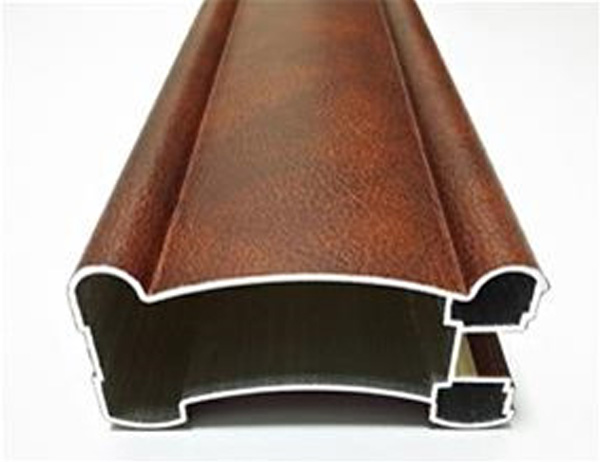

Product Details

Aluminum extrusion for wooden windows . Wood grain has strong adhesion to aluminum. It is non-toxic, odorless and easy to clean. Product lines clear, strong sense of three-dimensional appearance, good decorative effect, a return to the nature of the visual effect of recover the original simplicity. Sprayed aluminum surface coating, in the air is not volatile, no oxidation, no pollution to the environment. The dirt deposited on the surface of the spray can be restored to its original luster and appearance as soon as it is washed.

Process 1: suitable for large-area or special-shaped substrates

Suitable for large-area or special-shaped substrates

Step 1: select the base material that has been sprayed or sprayed

The second step: using wood grain thermal transfer paper to be transferred substrate wrapped, with high temperature adhesive tape fixed paper interface, in case the wood grain heat transfer paper release. (Note: the front surface of the wood grain heat transfer paper should be attached to the surface of the substrate to be transferred.)

The third step: to have been in the wood thermal transfer paper wrapped on the substrate over high temperature resistance and good sealing tubular plastic bags, then vacuum from two plastic bags, plastic bags and can fully and effectively close to the substrate.

Vacuum negative pressure size should be based on the characteristics of the transfer substrate and plastic bags can withstand negative pressure and other factors to make appropriate adjustments, usually between 0.3 ~ 0.8Mpa. (Note: the purpose of using plastic bags is to press the plastic bags that cling to the substrate by negative pressure so that the wood grain heat transfer paper can be fully and effectively attached to the substrate

The fourth step: the substrate has been wrapped to the baking oven, baking temperature and time should be adjusted according to the comprehensive factors of specific performance characteristics, transfer to the substrate by the depth and texture of the oven transfer, usually transfer temperature is 160 to 180 DEG C for 5 to 8 minutes.

The fifth step: remove from the oven has been transferred from one end of the substrate, the substrate transfer off the plastic bags (Note: this plastic bag can be used repeatedly, tear enrichment) thermal transfer paper, surface cleaning

Process 2: apply to flat substrate

Applicable to flat substrates

Step 1: select the base material that has been sprayed or sprayed

The second step: the wood grain thermal transfer paper front and the transfer of the substrate to the front of the shop

The third step: flat heat transfer machine pressure and heating, usually transfer temperature of 160~180 degrees, time is 18~25 seconds

The fourth step: tear off the heat transfer paper, use PET heat transfer film transfer