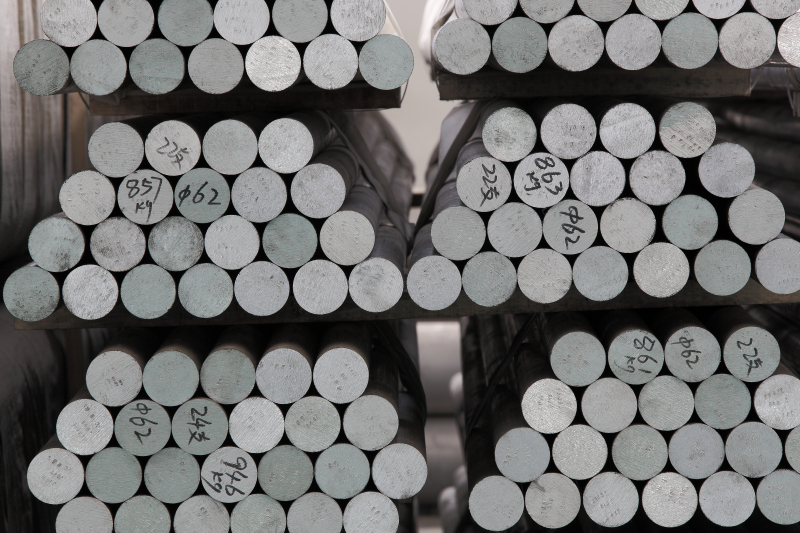

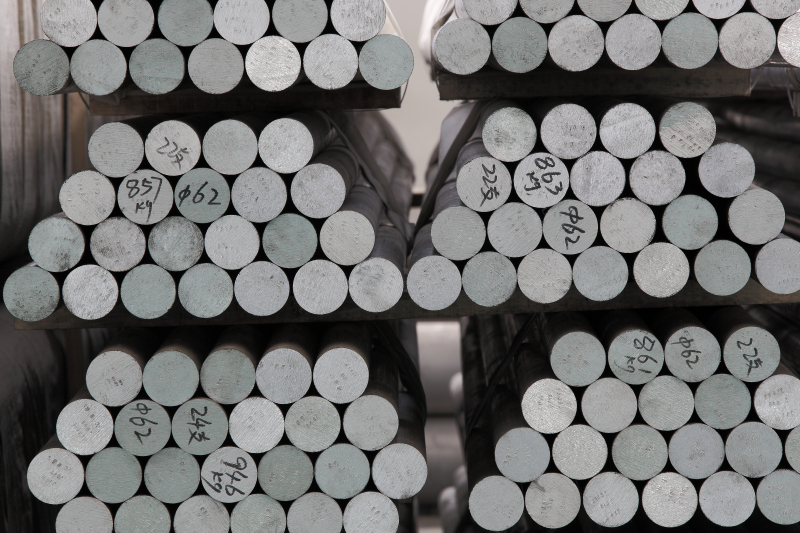

1Series Aluminium Alloy Extrusion

Product Details

1 series aluminum alloy means pure aluminum, the content of aluminum is not less than 99%, characteristics: more than 99.00% of aluminum, good electrical conductivity, good corrosion resistance, good welding performance, low strength, and can not be strengthened by heat treatment.

High-purity aluminum (more than 99.9% aluminum content) is mainly used for scientific experiments, chemical industry and special applications.

The 1 series aluminum alloys that our company can produce are as follows:

Bare package;

waterproof cloth / plastic film wrapping, steel band bundling, wooden pallet bottom;

cube packaging, wooden pallet bottom, steel band bundling

1. Sophisticated production technology, advanced equipment. The main production equipment and testing equipment are imported from abroad

2. High precision, high strength, corrosion resistance and wear resistance

3. The technical center (central laboratory) has been assessed as the Qinghai Engineering Technology Center. It is not only capable of analyzing the chemical composition of the aluminum alloy tube and rod production, metallurgical structure inspection, and mechanical property testing, but also can meet the needs of new product and new process development.

4. Certificates to prove quality:

01 Weaponry equipment research and production license

02 National Industrial Production License

03 Quality management system certification

04 Environmental management system certification

05 Occupational health and safety management system certification

Shipment:

Standard loading quantity:

1*20GP:Max .length:5.85 meters Loaded quantity: 10 to 12 tons

1*40HQ:Max. length:12 meters Loaded quantity: 22-26 tons

Standard export port:

Huangpu/ Foshan or Shenzhen

Type of shipping:

Shipment by sea; by road; by train; multi-transportation.

Knowledge

There are a number of aluminium extrusion manufacturers in Australia who can provide a range of extrusion products. This is good news for those looking to purchase products from this industry. It also serves as an indicator that this industry is growing and expanding, so support services are available should one become lost. With a good supplier in place, it is also possible to purchase components from this manufacturer that will be customised to meet exact requirements. Here are some key features of aluminium extrusion suppliers in Australia.

The first characteristic to note about aluminium extrusion manufacturers in Australia is that they have extensive experience in the field. This means that they are able to provide products that are precise to within a tolerance of plus or minus 0.002 millimeters. For those manufacturing parts for vehicles, safety is of paramount importance and this is reflected in the fact that the majority of suppliers are vehicle-specific. In addition, they will also have custom design capabilities, so they can manufacture parts that are suitable for any given vehicle.

Another important characteristic to note is that they will offer industry-leading production capabilities. This means that all aluminium extrusion manufacturer's equipment and machinery are designed and manufactured to the highest standards. These standards are designed to ensure that the aluminium used in their production is of the highest quality. Aluminium extrusion products may often be used in aerospace applications, but they are also found in many industries. They are particularly found in the automotive and construction industries and so a company that has this type of presence is of benefit to investors.

The next important characteristic to note is that they offer their customers outstanding after sales service. This is important for investors because after sales service is essential if the business does not succeed. With a provider that can continually provide support to customers, it is likely that they will continue to experience growth in their business. It is also important to note that some aluminium extrusion manufacturers only have one floor. This could be beneficial to investors because it would mean that the company would have less overhead than a larger company would have.

It should be noted that there are a number of aluminium extrusion manufacturers that operate solely online. These companies are able to meet the demands of their customers by operating their business from their homes. They may not have the staff and the facilities that larger firms have. However, they are able to operate with significantly less overheads. These firms are well-known for the high standards that they have and the high quality products that they sell. For investors, this is an important characteristic to consider.

The last common characteristic to note relates to the ability of suppliers to get custom quotes. When dealing with an aluminium extrusion manufacturer, it is always best to have quotes offered to you directly. This way you will be able to compare prices between various aluminium extrusion manufacturers. In addition, when getting quotes, you should make sure that the quotations include not only the materials, and the labor costs, but they should also take into account other costs such as packaging and transport costs. By getting these additional charges taken into account, you will be able to make an accurate analysis of the financial benefits of dealing with a particular aluminium extrusion manufacturer.

Factory